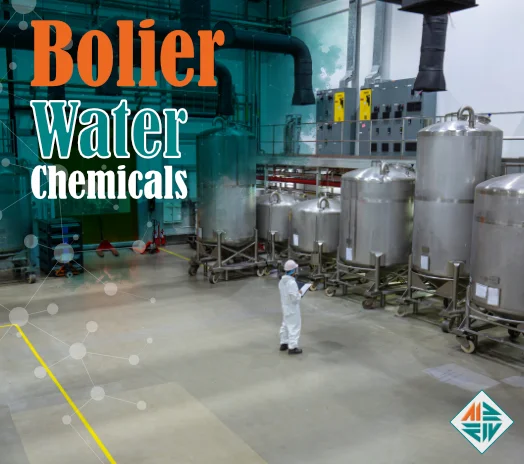

Boiler Water Chemicals

Revolutionizing Boiler Water Treatment : India's Cutting-Edge Chemical Solutions

We at Maxwell Additives offer a comprehensive range of top-notch boiler water chemical solutions designed to meet the diverse needs of industrial and commercial boiler systems. With years of expertise and a commitment to excellence, we understand that the efficient operation of your boilers is not just essential for your business; it's crucial for your peace of mind.

Our services encompass everything from selecting the right chemicals to ongoing monitoring and compliance, ensuring that your boiler system performs optimally while meeting all regulatory requirements. Welcome to the world of Maxwell, where your boiler's well-being is our top priority.

INQUIRY NOWOur Product Range

Our Product Range

OLKLIN-OSPS

Catalyzed partially neutralized Sulphite Oxygen Scavenger, preventing corrosion in industrial systems.

OLKLIN-OSLH

Your shield against corrosion, ensuring your boiler stays

rust-free.

OLKLIN-OSLS

Corrosion's worst enemy, safeguarding your boiler's longevity.

OLKLIN-OSLH+

Unmatched protection, preventing corrosion with advanced formula precision.

OLKLIN-PHBC

Balancing act for your boiler’s pH levels, ensuring stability and efficiency.

OLKLIN-PHBA-1

Precision pH control for optimized performance and prolonged boiler life.

OLKLIN-PHBA

Corrosion's worst enemy, safeguarding your boiler's longevity.

OLKLIN-AS(BW)-1

Superior phosphate treatment, preserving your boiler system's integrity.

OLKLIN-AS(BW)-3

Triple-action defense against contaminants, ensuring peak boiler performance.

OLKLIN-AS(BW)-2

Precision phosphate treatment, tailored for maximum corrosion prevention.

OLKLIN-SCL

Your boiler's cleanup crew, combating sludge for a pristine, efficient system.

OLKLIN-SCL-1

Advanced sludge control, ensuring your boiler operates at peak efficiency.

OLKLIN-FA

Enhancing fuel efficiency, one drop at a time, ensuring your boiler runs at its best.

OLKLIN-FACOAL

Tailored for coal-fired boilers, optimizing combustion and maximizing energy output.

OLKLIN-DS

A highly active descaling agent, OLKLIN-DS, utilizes HCl and a specialized film-forming inhibitor for efficient scale removal in industrial applications.

OLKLIN-DS-1P

OLKLIN-DS-1P is an inhibited sulfamic descalant powder, designed for convenient and efficient descaling operations in powdered form.

OLKLIN-DS-2A

OLKLIN-DS-2A acts as a versatile descalant and cleaner, suitable for a variety of industrial equipment and systems.

OLKLIN-DS-4-P

OLKLIN-DS-4-P, an alkaline cleaner in powdered form, delivers robust descaling capabilities, essential for industrial maintenance.

OLKLIN-DS(RAD)

This descaling and corrosion inhibition composition is formulated for closed systems, providing effective scale removal and corrosion protection.

OLKLIN-DSOL

OLKLIN-DSOL is a dynamic online scale remover suitable for both cooling and boiler systems, ensuring continuous operation and system efficiency.

IMPORTANCE

Functions of Boiler Water Chemicals

Prevent Corrosion

Boiler water chemicals inhibit corrosion of metal surfaces within the boiler, ensuring the longevity and efficiency of the system.

Scale Prevention

These chemicals control mineral scaling, preventing the buildup of deposits on heat transfer surfaces, which can decrease heat exchange efficiency.

Oxygen Scavenging

Boiler water chemicals remove dissolved oxygen from the water, preventing oxygen-induced corrosion, which can damage the boiler and associated equipment.

Microbiological Control

They also help in controlling bacteria and algae growth in the water, ensuring a clean and safe environment within the boiler system.

Benifits of Boiler Water Chemicals

Enhanced Efficiency

Boiler water chemicals optimize heat exchange, reducing energy consumption.

Extended Equipment Life

Prevents corrosion, increasing the lifespan of boiler components.

Minimized Downtime

Reduces system failures, ensuring continuous operation and productivity.

Safety and Compliance

Maintains a safe environment, ensuring regulatory adherence and legal compliance.

Applications of Boiler Water Chemicals

Industrial Boilers

Used in various industries like manufacturing, refineries, and textiles to maintain efficient and safe boiler operation.

Power Plants

Critical in power generation facilities, preventing corrosion and scale in steam generators, ensuring reliable electricity production.

HVAC Systems

Applied in heating, ventilation, and air conditioning setups to prevent scale buildup in boilers, ensuring efficient climate control.

Food Processing

Utilized to maintain clean and sanitized boilers, crucial in food and beverage processing to meet hygiene standards.

Hospitals

Ensures sterilization and cleanliness in steam boilers, vital for functions like sterilizing medical equipment and providing hot water.

Commercial Buildings

Employed in large buildings with centralized heating systems, enhancing energy efficiency and reducing operational costs.

Monitoring and Testing

At Maxwell Additives, we don't just provide chemicals; we offer a comprehensive package that includes ongoing monitoring and testing. Our commitment to maintaining water quality ensures that your boiler system remains in peak condition, year after year.

Regulations and Compliance

We keep abreast of industry regulations and compliance standards so you don't have to. Rest easy knowing that our services not only optimize performance but also ensure you remain compliant with all relevant regulations, safeguarding both your business and the environment.

Common Boiler Water Problems

Selecting the Right Chemicals

Our expertise doesn't stop at delivering chemicals; it starts with helping you select the right ones. We work closely with you to understand your specific needs, providing tailored recommendations and tips for working with reputable suppliers. Your success is our success.

FAQ's

Boiler water chemicals are essential because they help prevent problems like scale formation, corrosion, and microbial growth, which can lead to reduced efficiency, costly repairs, and even safety hazards. These chemicals play a crucial role in maintaining the longevity and optimal performance of boiler systems.

Selecting the right chemicals depends on factors such as your boiler type, operating conditions, water quality, and specific challenges you may face. Consulting with a water treatment expert or supplier is advisable to ensure that you choose the most suitable chemicals and treatment strategy for your needs.

Yes, regular monitoring and testing of boiler water quality are essential. Water conditions can change over time, and monitoring helps detect issues early, preventing damage and downtime. Routine testing ensures that chemical treatment levels are within the desired range and that the boiler operates safely and efficiently.

The frequency of testing depends on factors like boiler usage, water quality, and chemical treatment. Typically, monthly tests are recommended, but more frequent testing might be necessary in certain conditions to promptly address any emerging issues.

Properly selected and dosed chemicals are designed to be safe for both the environment and human health. However, it's important to follow recommended guidelines and regulations to prevent any adverse effects. Regular monitoring ensures the chemicals are within safe limits.

Untreated water can lead to scale formation, corrosion, and microbiological growth, all of which decrease boiler efficiency. This inefficiency results in higher energy costs, reduced heat transfer, and increased wear and tear on equipment.

Yes, there are often environmental regulations and compliance standards governing the use and discharge of boiler water treatment chemicals. It's crucial to stay informed about these regulations to ensure that your system complies with environmental guidelines and avoids any potential legal issues. Working with a reputable water treatment provider can help you navigate these regulations effectively.

Different types of boilers (e.g., fire tube, water tube) have unique operating conditions. It's crucial to choose chemicals compatible with your specific boiler type to ensure effective treatment. Consultation with a water treatment expert can help determine the appropriate chemicals for your system.

pH levels influence the effectiveness of boiler water chemicals. Maintaining the correct pH range is essential; too high or too low pH can lead to corrosion or scale formation. Regular testing and adjustment of pH levels are integral parts of boiler water treatment.

While effective chemicals significantly reduce the need for manual cleaning, they may not eliminate it entirely. Regular inspections and preventive maintenance are still necessary to ensure the system's optimal performance and longevity. Chemicals complement these efforts but do not replace them entirely.